Quick Facts About Car Suspension Systems

- A car suspension system helps the vehicle drive smoothly by absorbing surface imperfections like depressions, corrugation, and potholes.

- If your car’s steering pulls left or right, it’s a sign the suspension might be off.

- The suspension system is the bridge between your vehicle and its wheels.

Your car’s suspension system typically requires only minimum maintenance. However, as with any of a car’s moving parts, the suspension components can eventually wear out. Also, if you haven’t kept up with the car’s recommended scheduled maintenance or it has recently sustained a suspension-damaging impact, it will provide warnings if it is in distress. Here, we will provide the signs that will alert you that something is amiss and it’s time for some suspension repair or replacement. We’ve provided jump links if you want to skip ahead.

Do Suspension Systems Wear Out?

10 Signs Your Suspension Is Bad

How Much Will a Suspension System Repair Cost?

3 Tips to Help Avoid Expensive Suspension Repairs

What Is a Car Suspension?

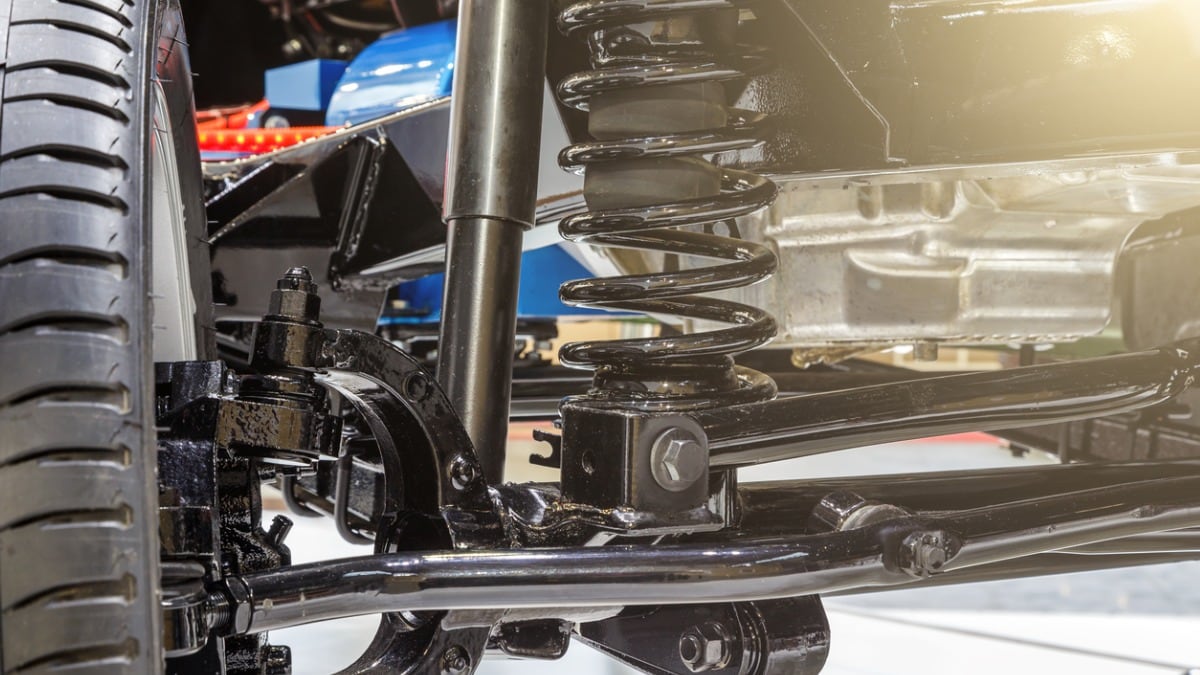

A car’s suspension is a collaboration of springs, shocks, struts, and other parts that serve to stabilize your car’s platform while absorbing surface inconsistencies to help maintain passenger comfort. Think of a vehicle’s suspension as the bridge between the vehicle body and its wheels. Ensuring a smoother ride, it absorbs depressions, surface corrugation, potholes, and other imperfections. Although hitting a pothole can be jarring, it would feel much worse without a functioning suspension system. Moreover, when properly tuned, the suspension also helps maximize the contact between your vehicle’s tires and the road. In other words, it contributes to your car’s handling and steering.

RELATED: Do My Tires Need to Be Replaced?

What Are the Components of a Car Suspension?

There are far too many pieces and parts that make up a car’s suspension to detail here. For example, things like bushings, mounts, and other secondary players also contribute to suspension architecture and can wear out. However, we’ll confine ourselves to spelling out the more major suspension components.

- Leaf spring: An older technology that today can be found on certain body-on-frame trucks, SUVs, and vans, consisting of multiple layers of steel between the axle and frame that act to absorb surface imperfections while supporting the vehicle’s weight. Once also common on cars, leaf springs have been gradually replaced with coil springs.

- Coil spring: An elasticized spiral of steel between the axle and frame of a vehicle that absorbs motion as it helps support the vehicle’s weight.

- Shock absorber: Sometimes called a shock or a damper, it is a tubular device that uses friction to mitigate the force of the expansion and contraction of a leaf or coil spring. In other words, it softens the force of the spring’s reaction to bumps. A contracting spring forces a piston down the shock’s cylinder, compressing fluid and forcing it into a reservoir between the wall of the cylinder and the outer wall of the tube. The spring expanding to its normal length draws the piston back up the cylinder, sucking the fluid back out of the reservoir.

- Strut: Whereas a shock and spring are individual components, a strut combines a shock with a coil spring into a single unit. Suspensions using struts rather than shocks and springs are lighter, less complicated, and more affordable while basically performing the same function. The strut is the key component of a MacPherson strut suspension.

- Control arm: This is the suspension component that attaches the wheel to the vehicle’s frame. A traditional suspension with independent shocks and springs has an upper and lower control arm at each wheel. A strut suspension only requires a lower control arm, which is one reason why it is lighter than a shock/coil spring suspension.

- Ball joint: This component joins the control arm to the wheel. Engineered to pivot in more than one direction at a time, it makes it possible to turn the wheel in one direction or another while still allowing it to move up and down as it reacts to bumps.

- Sway bar: Also called an antiroll bar, torsion bar, or stabilizer bar, it ties together the two wheels on the same axle. As you enter a curve, the suspension on the outside wheel contracts while the inside wheel’s suspension expands, causing a rolling effect. The sway bar is U-shaped with its closed end pointed forward. As the suspension reacts to the curve, the sway bar twists, resisting and minimizing the rolling effect. The thicker the sway bar, the less body roll.

What Is an Adaptive Suspension?

Although it can take various forms, basically an adaptive suspension incorporates an electronically controlled damper into a coil spring/shock absorber or strut setup. Often, the driver may pick among various suspension settings, such as comfort or performance to manually set the suspension’s driving dynamics. These systems can also use sensors to measure changing conditions like vehicle speed and surface conditions to automatically adjust to maximize the driver’s chosen setting

RELATED: What Is Adaptive Suspension?

What Is an Air Suspension?

Think of an air suspension as a more sophisticated adaptive suspension. It significantly increases the comfort, performance, versatility, and cost of a vehicle’s suspension. In essence, it replaces the coil spring with an air bladder, which now assumes the spring’s load-bearing duty. Yes, it usually includes multiple settings to suit a driver’s preferences or driving conditions. Air suspension’s major advantage over other adaptive suspension schemes is adjustable ride height. Capable of raising and lowering the vehicle chassis, an air suspension is particularly beneficial when off-roading, towing, and loading Grandma in the backseat. However, even in everyday use, it can deliver a more pliant ride than a traditional suspension system.

Do Suspension Systems Wear Out?

Yes, even the most careful drivers will see their vehicle’s suspension suffer the effects of time and normal wear and tear. A complex system, your car’s suspension will probably not fail entirely. However, one by one, its components will eventually fail. Each failure, if neglected, will reduce the suspension’s effectiveness.

What Is the Life Expectancy of Suspension Parts?

Under normal conditions, you can expect suspension system components to last from 50,000 to 100,000 miles. Indeed, that’s quite a spread; however, there are several factors that can impact a suspension’s life span:

- Aggressive driving

- Bad roads

- Improper tire pressure

- Extreme temperatures

- Repeatedly exceeding a vehicle’s payload limit

- Exceeding a vehicle’s maximum towing limit

- Ignoring the warning signs of misaligned wheels

Modern Suspension Diagnostic Technology

As with just about everything else today, diagnosing suspension issues is more reliable and available than ever before. The technology has reached the point that, when in the hands of a trained professional, scanners can identify component issues before they become a serious (and potentially dangerous) problem. Of course, the burden of ensuring a car receives such comprehensive inspections rests with the owner.

10 Signs Your Suspension Is Going Bad

If properly maintained, your vehicle’s suspension system can last a long time. However, erratic or overly aggressive driving and other factors can shorten the suspension’s life. More about that below.

Gary Hardesty is an ASE certified master technician and Kelley Blue Book’s in-house service and maintenance expert. He provided us with several telltale signs indicating that something could be wrong with your car’s suspension.

1. Difficulty Steering

When driving, the steering wheel should be steady. The suspension and steering systems go hand-in-hand, so if the steering wheel feels shaky, loose, or abnormally stiff, the issue could be with the suspension.

2. Vehicle Pulling to One Side

If the car pulls to the left or the right as you drive, it’s usually a sign the front wheels are out of alignment or some suspension component is failing.

EXPERT TIP: Prolonged driving with misaligned wheels will put undo stress on other suspension components, causing them to eventually fail, as well.

3. Excess and Uneven Tire Wear

Cupping and ridges in your tires are a signal your suspension may be failing.

Although some instances of uneven tire wear can be blamed on improper air pressure, often the cause is a faulty suspension. When the shocks, springs, or bushings go bad, they can no longer maintain the appropriate alignment, causing uneven distribution of weight on the tires.

4. Leaking Around Shocks and Struts

A fluid leak from the area around the tires could be the shocks or struts. Multiple puddles of fluid usually translate into a repair. Consequently, if you encounter a leak around or above your tires, we recommend a visit to a service and repair center to have a professional check out the problem.

5. Unusual Noises

If you suddenly notice squeaking, clunking, or knocking sounds when driving over bumps, it’s often a signal that one or more suspension components are failing.

6. Car Bounces After a Speed Bump

A speed bump helps ensure you are maintaining the speed limit, particularly in residential areas with high pedestrian traffic. However, it may also serve as an early warning system that your suspension is failing. For example, if your car continues to bounce after going over a speed bump, worn springs or struts may be the culprit.

As the suspension wears out, the springs and shocks, or struts lose their elasticity. In other words, they don’t rebound as well as they should.

A quick way to test if your car’s suspension is bad is by pressing down on the rear bumper when parked. Once you let go, it should just go back in place. But if it is bouncy and doesn’t return to its normal position, the suspension is failing.

7. Vehicle Leaning to One Side

One corner or one side of a vehicle resting lower than the other usually indicates a damaged spring, causing the vehicle to list.

8. Abnormal Swaying or Body Roll

Excessive swaying or body roll when taking curves indicates the suspension isn’t properly stabilizing the vehicle. This is often a sign that suspension components are failing.

9. Diving or Squatting

If during normal braking, the front end (nose) dips or dives, it’s a clear sign of some suspension failure, which is also true if, when normally accelerating, the rear end squats. More often than not, worn shocks or struts are the culprit.

10. Bottoming Out

When the suspension system can no longer fully support the weight of the vehicle, the chassis will come in contact with the road with every small bump. This is called bottoming out. As it grows more severe, it puts other mechanical components like the oil pan and transmission at risk, too. It’s also a safety issue because you may lose steering control. To reach the point of bottoming out, you’ve undoubtedly disregarded one or more of the other warning signs we’ve listed. You absolutely shouldn’t ignore this one.

How Much Will a Suspension System Repair Cost?

The odds of your entire suspension system failing at the same time are slim. As we’ve already mentioned, the suspension is a collection of components that, more than likely, will fail sporadically. What we can tell you is, if you should have to address issues at all four wheels, you would be looking at between $2,800 and $5,500. This would be for mainstream models rather than high-end luxury models.

3 Tips to Help Avoid Expensive Suspension Damage

Although we’ve already established that suspension components will wear out over time regardless of driver behavior or attention, there are a few actions drivers can take to avoid hastening that process.

- Drive sensibly: Extreme weather-caused damage and lack of regular road maintenance mean most drivers are forced to navigate potholes and corrugated surfaces every day. Moreover, installed speed bumps, rough railroad crossings, pavement disruptions from road repair, and other human-caused imperfections add to the problem. In other words, today’s roads are a risky environment for a vehicle’s suspension. Overly aggressive driving multiplies the threat. It increases the force of impact with every road imperfection encountered. The greater the force of impact, the more likely suspension components will sustain an increased degree of wear and tear if not outright damage. If you can’t avoid badly damaged surfaces, at least slow down to minimize the impact.

- Don’t ignore the warning signs: Any one of the warning signs we listed above can lead to more severe damage if not addressed. They won’t go away on their own. Spending the money now to repair whatever the suspension issue might be will save you even more money down the road.

- Regular inspection and maintenance: There is no mystery. Suspension components will wear out and eventually fail. Regular periodic inspections by a trained professional can often reveal suspension issues before they become serious problems. We recommend always following the scheduled maintenance as outlined in your vehicle’s owner’s manual.