- Carbon-fiber based molded bed for GM’s half-ton pickup

- The strongest pickup bed GM has ever offered

- About 60 pounds lighter than its steel counterpart

- Impact, dent, chemical, UV, and corrosion-resistant

- Offered on Denali trims at introduction

Why make a CarbonPro pickup bed?

Pickup beds take a lot of abuse. Early beds, made of wood planks, were too soft and susceptible to damage from sharp items and liquids (not to mention termites and rot). Steel beds were much stronger, but the ferrous material (which must be painted to slow corrosion) was heavy, vulnerable to impact damage, and it eventually rusts. Aluminum is the latest trend in pickup bed construction (made popular by the Ford F-150), as it is light and very corrosion-resistant – yet it is still dented and damaged by impact.

GM has announced an all-new pickup bed material called CarbonPro. The man-made composite is touted to be lightweight, corrosion-resistant, chemical resistant, dent and impact resistant, and UV stable (unaffected by sunlight). In a nutshell, GM is promising the best of all worlds with this new material.

How is the CarbonPro pickup bed made?

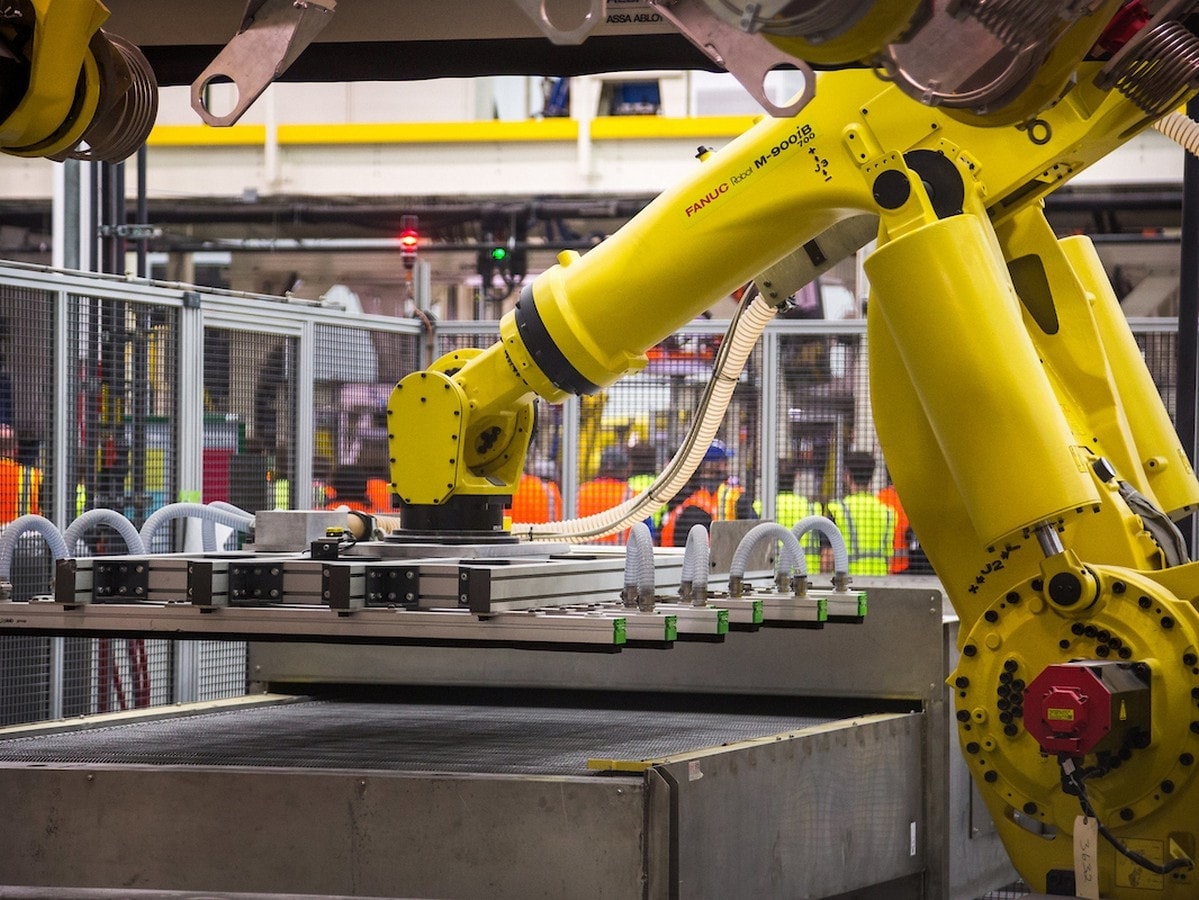

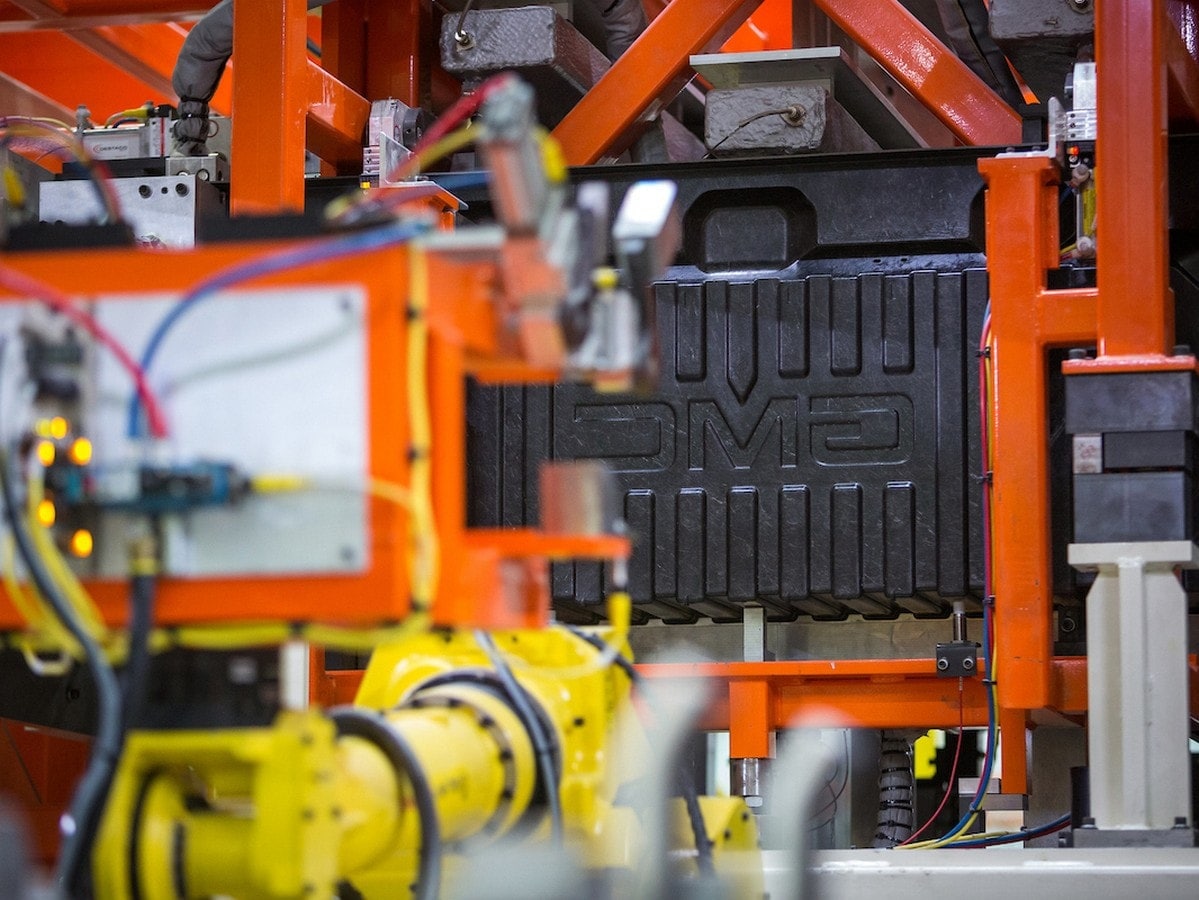

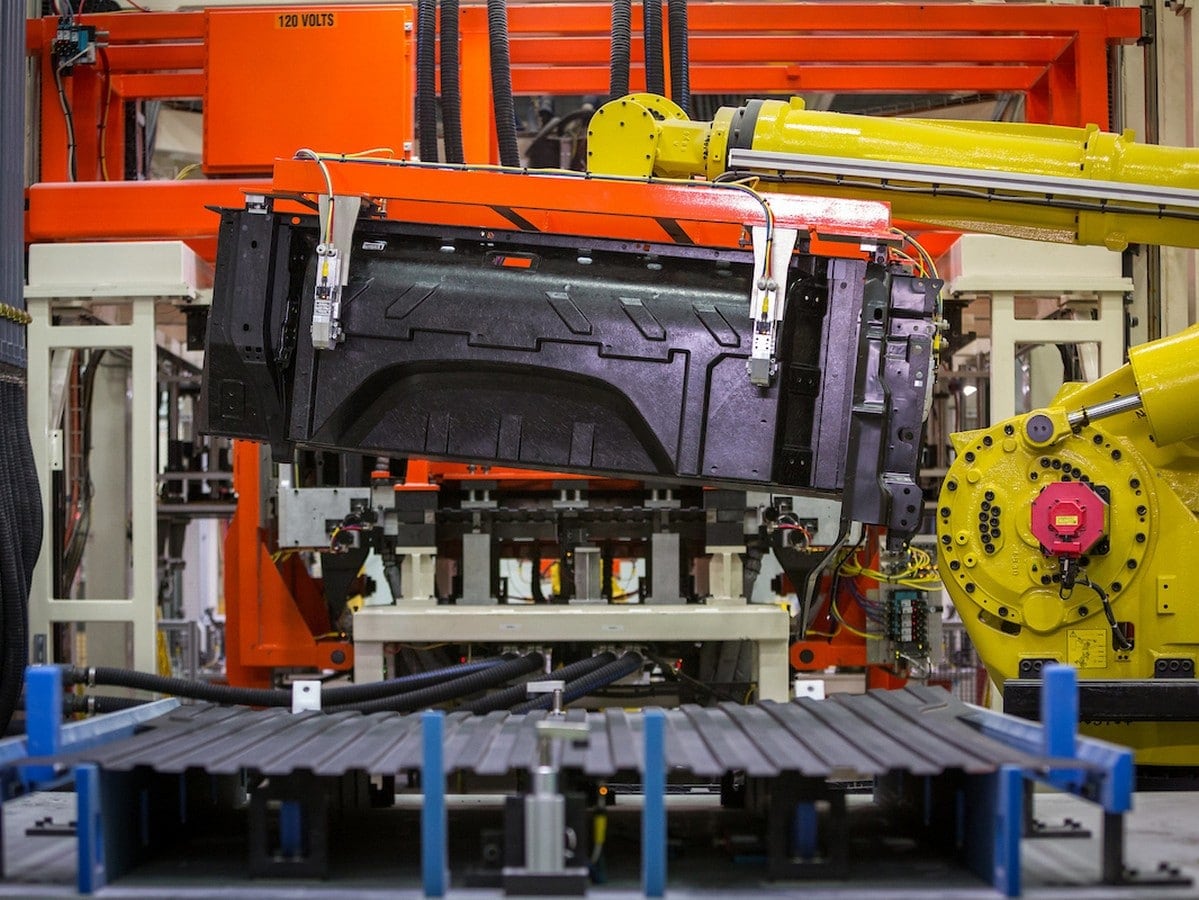

All CarbonPro pickup beds are currently made at Continental Structure Plastics (CSP), which is located in Fort Wayne, Indiana. The company has decades of experience as a trusted supplier of automotive composites – they have been crafting Chevrolet Corvette body panels and the detachable hard top on the Jeep Wrangler for years.

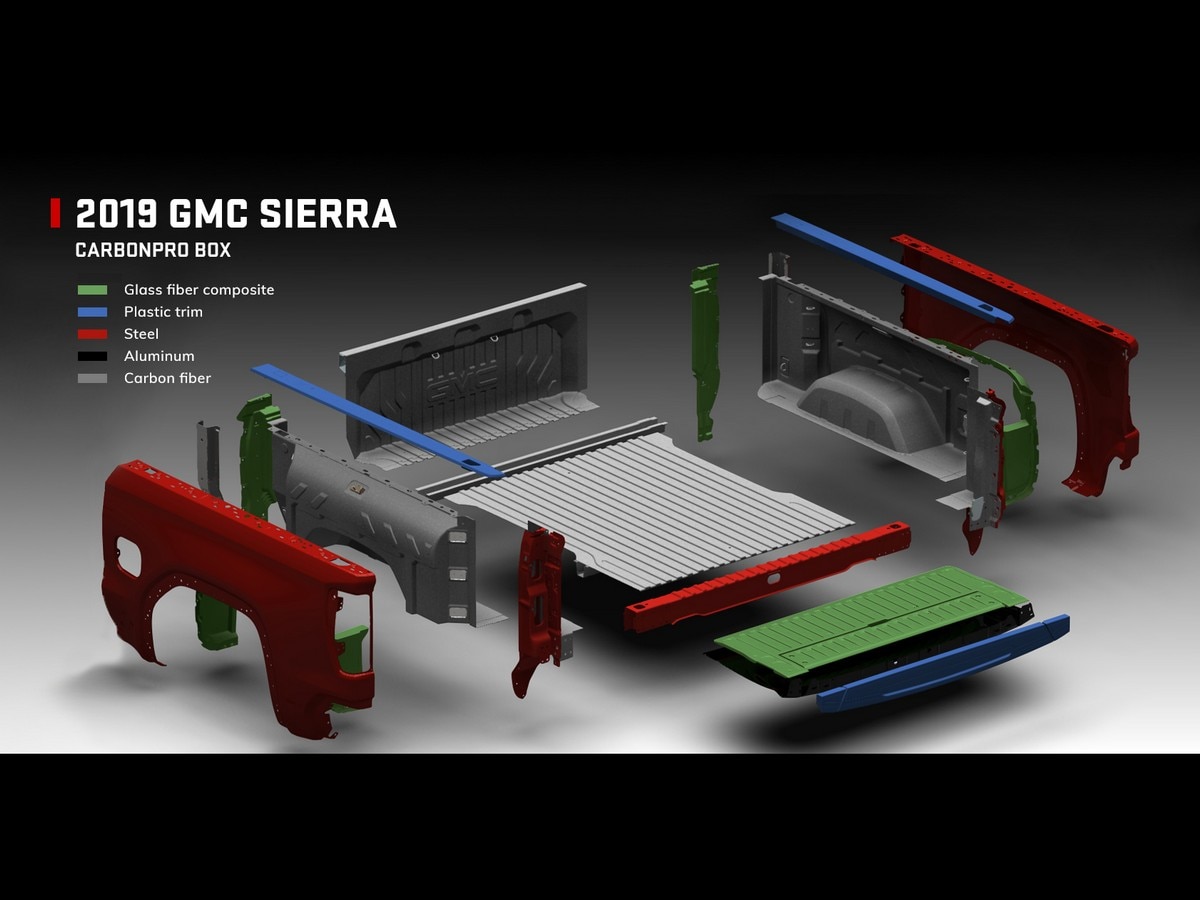

Manufacturing the CarbonPro bed is more complicated than it initially sounds as the construction utilizes four different materials: carbon fiber composites, reused carbon fiber composites, glass fiber composites, and steel. Each material is used strategically, to optimize its material strengths. The composites are used on the bed floor and sidewalls (where they will see the most abuse). Reused composites are made into structural parts on the rear, and glass fiber composites are used in the wheel wells. Lastly, GM will make the exterior bed panels in traditional steel for easy, low cost, replacement if they are damaged in daily use – they will be painted body color.

Many premium automakers are using carbon fiber today, but the CarbonPro composite bed and sidewalls aren’t constructed in the same manner as the carbon fiber panels on, say, an F1 race car. Those are wafer-thin woven fabric sheets that are bonded with tough resins (while strong, that material would be too expensive to manufacture and far too brittle for use in a pickup bed). Instead, inch-long strands of carbon fiber are blended with nylon and other resin materials to create CarbonPro. The material, in a semi-molten state, is pressed into shape with 2,500-ton SMC (Sheet Molded Compound) presses. In some applications, such as the bed floor, sheets are double layered for additional strength and texture is added to increase grip.

Is CarbonPro stronger than steel and aluminum?

In durability tests, GM’s new CarbonPro bed has proven immensely durable and strong – arguably stronger than its metal counterparts. General Motors touts it as, “The most corrosion, dent and scratch resistant bed in the industry.”

The new CarbonPro bed should be more durable than its steel and aluminum counterparts – assuming the tradition metal beds don’t have any coating or lining. GM has done extensive testing for tensile strength, flex, impact resistance, fatigue, creep, galvanic corrosion resistance, chemical resistance, weather, and temperature. Based on those tests, the composite material outperforms its metal rivals.

However, we must keep in mind that most pickup truck owners apply a tough polyurethane coating to their metal beds these days, either as a factory option or aftermarket (e.g., Rhinolining). These “spray-in bed liners” are durable, add texture to the slippery surface, and they absorb vibration (helping to protect the cargo and lower noise). However, they are susceptible to fading and cracking from long-term UV exposure. GM has not made any claims comparing its CarbonPro to a steel or aluminum bed with a spray-in liner.

Are there drawbacks to the CarbonPro pickup bed?

Initial drawbacks will be cost. Production at CSP is slow as the company ramps-up to full speed (current production is only about one pickup bed every ten minutes). To bring costs down to a reasonable level (spray-in bed liners are only about $450 installed), production rate and volume must increase significantly. GM will likely lose money on first year production, and will bundle the CarbonPro bed with highly profitable AT4 and Denali trims on the GMC Sierra).

Other drawbacks include potential noise as cargo slides around the bed (stiff sheets of carbon fiber sound like sheets of metal when scratched and banged on), and the fact that passers-by won’t be able to see the CarbonPro pickup bed because the walls of the bed are conventional painted steel – most owners will want to show this innovative technology off.

Where can I buy a CarbonPro pickup bed?

The CarbonPro pickup bed will initially be available on GMC Sierra pickup trucks with the Denali and AT4 trims. GM has not announced pricing.

Don’t want to wait? Check out the 2019 GMC Sierra to see what’s available near you.